World of Smart Homes

The almost-panacea(*) for the industrialized construction of buildings

* = the solution for everything

-

- World of Smart Homes (WoSH) addresses the key risks and opportunities of global building construction

-

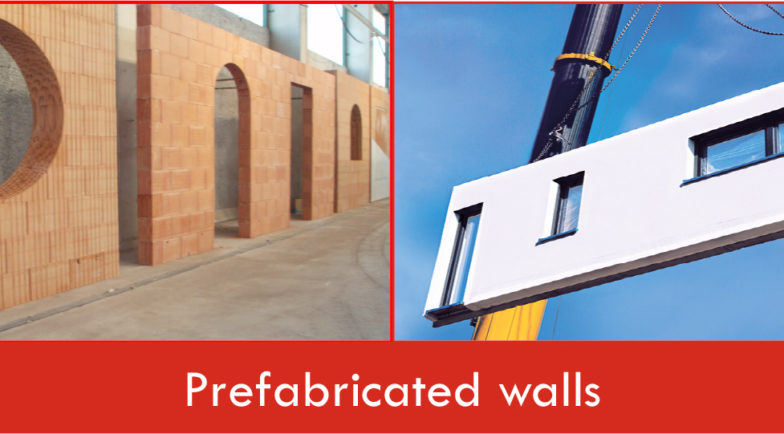

- The WoSH building system and scalable factories methodology provides you

with your preferred construction elements or complete buildings, as per your

beautiful and customized designs.

- The WoSH building system and scalable factories methodology provides you

INSTALLATION ANIMATION

WHY WoSH?

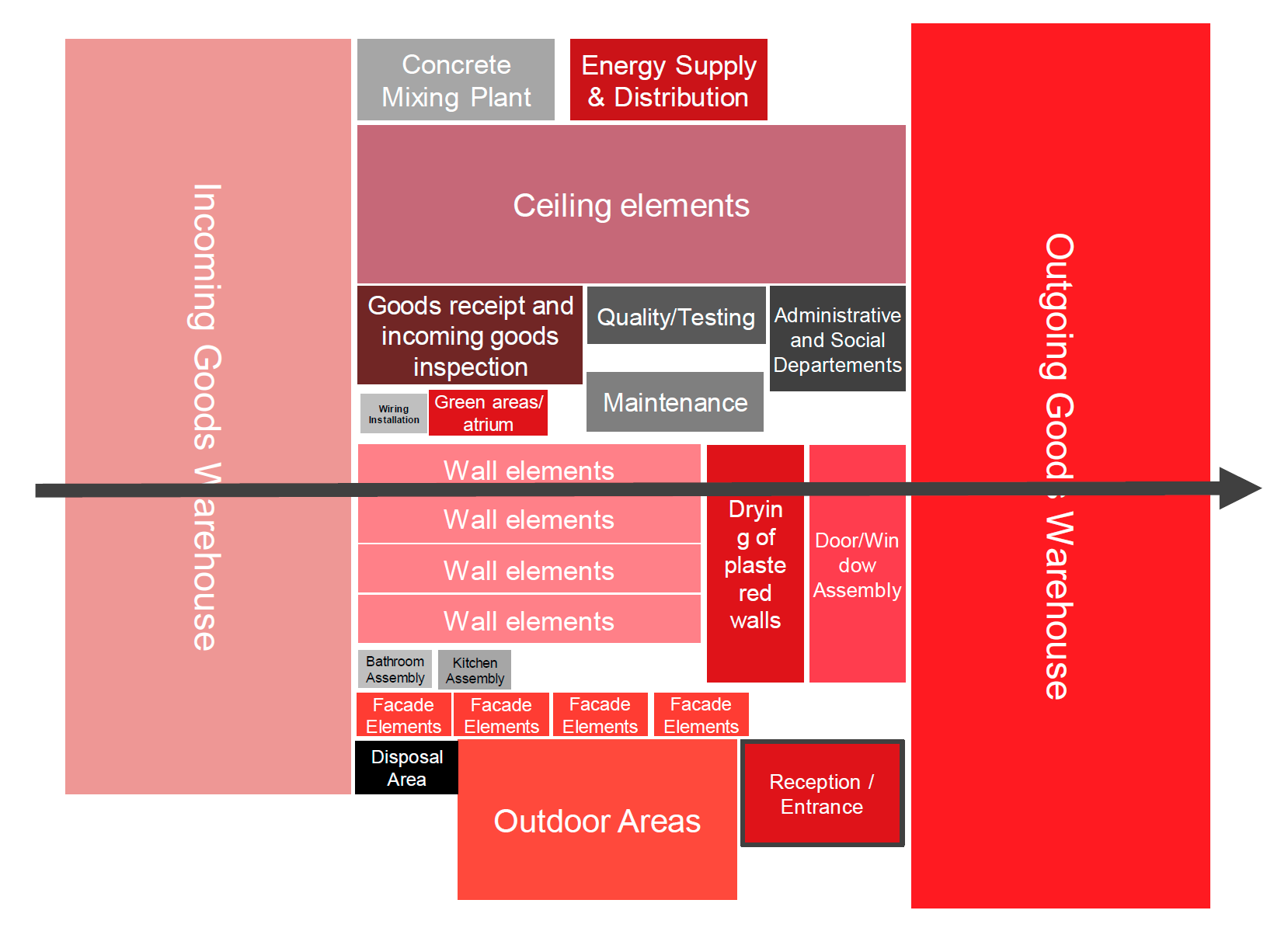

WoSH FACTORY LAYOUT